The process of injection mold manufacturing is complicated and complicated, and there are many processes behind the seemingly simple operation. Do you know what the injection mold manufacturing process is? Now let me tell you in detail, the injection mold production process mainly includes: accepting customer's customized needs, engineering team mold design, mold manufacturing, mold inspection and mold trial, mold modification and repair, and mold maintenance. The following Canglory technology (China) LTD will take you to understand one by one:

1. Accept the customized needs of customers

The production of plastic molds, first of all, the customer engineers provide product drawings or physical objects to the mold manufacturer. The manufacturer needs to understand the technical requirements such as the use, craftsmanship, and dimensional accuracy of the plastic parts. Through the task requirements of molding plastic production, collect, The process of analyzing and digesting product data, which is to accept the customized needs of customers.

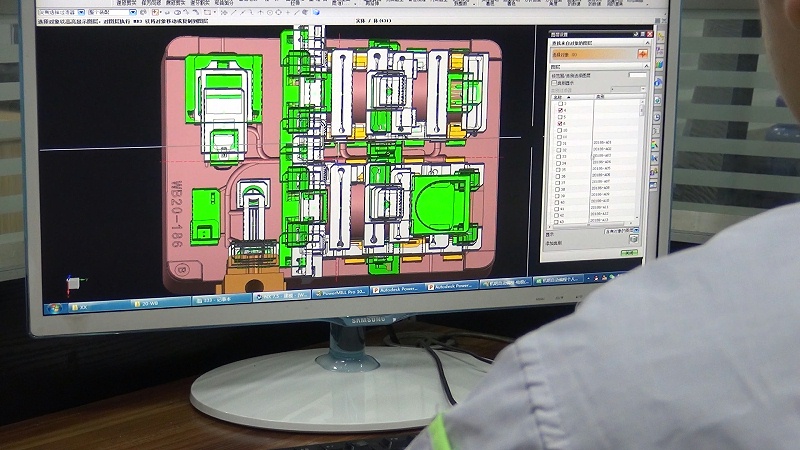

2. Mold design

The engineering team designs the mold structure according to the product drawings, ranks and draws the drawings

1. Ranking of plastic parts

Ranking of plastic parts refers to arranging one or more plastic parts required by reasonable injection molding process and mold structure according to customer requirements.

Ranking of plastic parts complements the mold structure and plastic manufacturability, and directly affects the injection molding process in the later stage. The corresponding mold structure must be considered when ranking, and the ranking must be adjusted under the conditions of satisfying the mold structure.

2. Drawing of quotation diagram and ordering materials

The quotation diagram is the initial design scheme of the mold, and also provides a reference for the mold ordering. The quotation diagram is a relatively detailed identification of the mold base and its structure and the size of the mold meat on the basis of the original mold arrangement. Ordering is based on the quotation diagram, draw a schematic diagram of the mold blank, and fill in the order form.

3. Mold structure design

The mold structure is determined by the type of injection machine and the characteristics of the plastic parts. The design focuses on the following aspects:

(1) Technical specifications of the injection molding machine;

(2) Process performance of plastic;

(3) Gating system, including runners, gates, etc.;

(4) forming parts;

(5) Commonly used structural parts;

(6) Position agency;

(7) ejection mechanism;

(8) Mold temperature control;

(9) Exhaust;

(10) Mold material.

Canglory technology (China) LTD is a one-station service manufacturer from mold design, injection mold processing, product injection production, plastic shell surface treatment (oil injection, silk screen, etc.) We, Shibang Plastics, are an enterprise run by love. Our aim is to create a happy enterprise. We focus on solving various customized problems for customers.